Launder Transfer Pumps

Transfer metal safely and effectively with MMEI’s Mini or Workhorse launder transfer pumps.

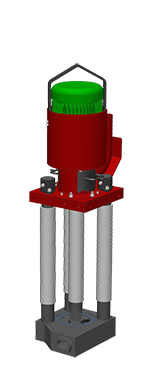

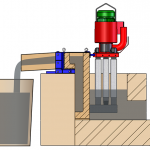

Designed with a robust shaft and rotor, MMEI’s launder transfer pumps provide maximum life expectancy and low maintenance costs. With our patented engineered design, replacing parts and servicing your pump is very maintenance friendly. In most cases, a shaft/rotor change can be accomplished in about an hour. As a result, your down-time is reduced and your productivity increases, all while improving metal yields and reducing melting costs.

Applications:

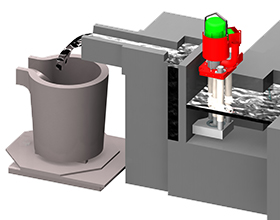

Filling Ladles

Transfer between Furnaces

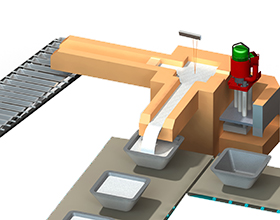

Feeding Casting Lines

Models:

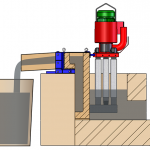

WORKHORSE Launder Transfer Pump

MINI Launder Transfer Pump

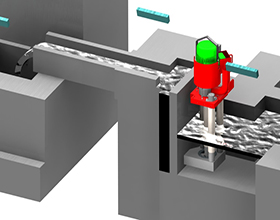

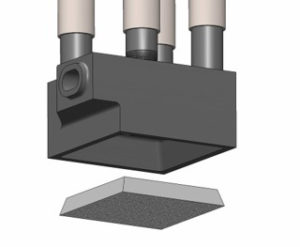

MMEI transfer pumps can also be used to filter your metal! We utilize a ceramic foam filter on the bottom of the pump, and our unique bottom feed rotor to deliver cleaner metal, every time!

FEATURES

- Available in 3 sizes: Workhorse, Mini & Mighty Mite

- Unique mixed-flow rotor generates more flow & lift

- Large, robust components

- Advanced material protective sleeve protection on shaft and posts

- Self-aligning design – no alignment fixture required

- Driven with high-efficiency electric motor

- Available with filter on inlet

- Eliminates need for riser and refractory lined piping

BENEFITS

- We have the right size for your application

- Generates more flow and higher lift for superior performance

- Engineered for the harsh environment

- Provides longer service life

- Easy to assemble and repair, reduces maintenance & downtime

- Provides precise control of pump operation

- Clean metal before transferring, improve casting quality

- Reduces part consumption and lowers operating costs

PROCESS INFO

OTHER PROCESSES

Molten Metal Transfer

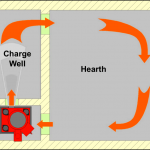

Furnace Circulation

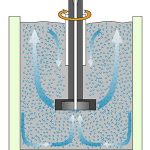

Degassing Process

Gas Injection

Molten Metal Transfer

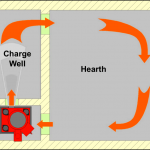

Furnace Circulation

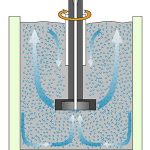

Degassing Process

Gas Injection