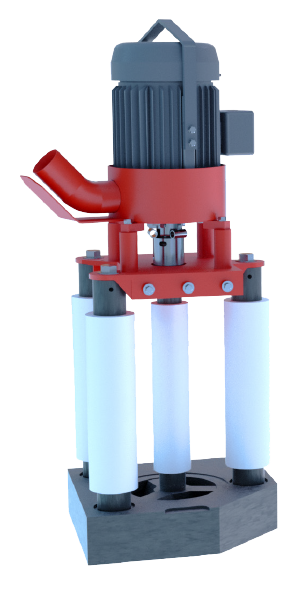

Smart Pump Technology

Advanced control system automatically controls speed of pump based on furnace operating conditions

- Control pump based upon furnace operating conditions

- Uses a variety of sensors to read temperature, metal level, vibration and more

- Pump speed adjusts automatically to increase furnace productivity, reduce manpower, and increase pump service life

- Reduces man-power requirements to operate furnace

- Improves pump service life

- Improves furnace productivity

- Provides a fast payback

RESOURCES