HYDRA Transfer Pumps

Experience the future of molten metal transfer with MMEI’s HYDRA Transfer Pump

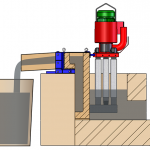

The HYDRA Transfer Pump has the ability to be configured with launders, transfer piping, and heated piping for dosing applications. Expect clean transfers, high lifts, and rapid dosing, all in a design built for efficiency and durability. The small footprint allows for a fit in tighter spaces, while the rugged construction is built with the harsh molten metal environment in mind. Available in three sizes tailored to your needs: the Mini, the Workhorse, and the Kong models.

RESOURCES

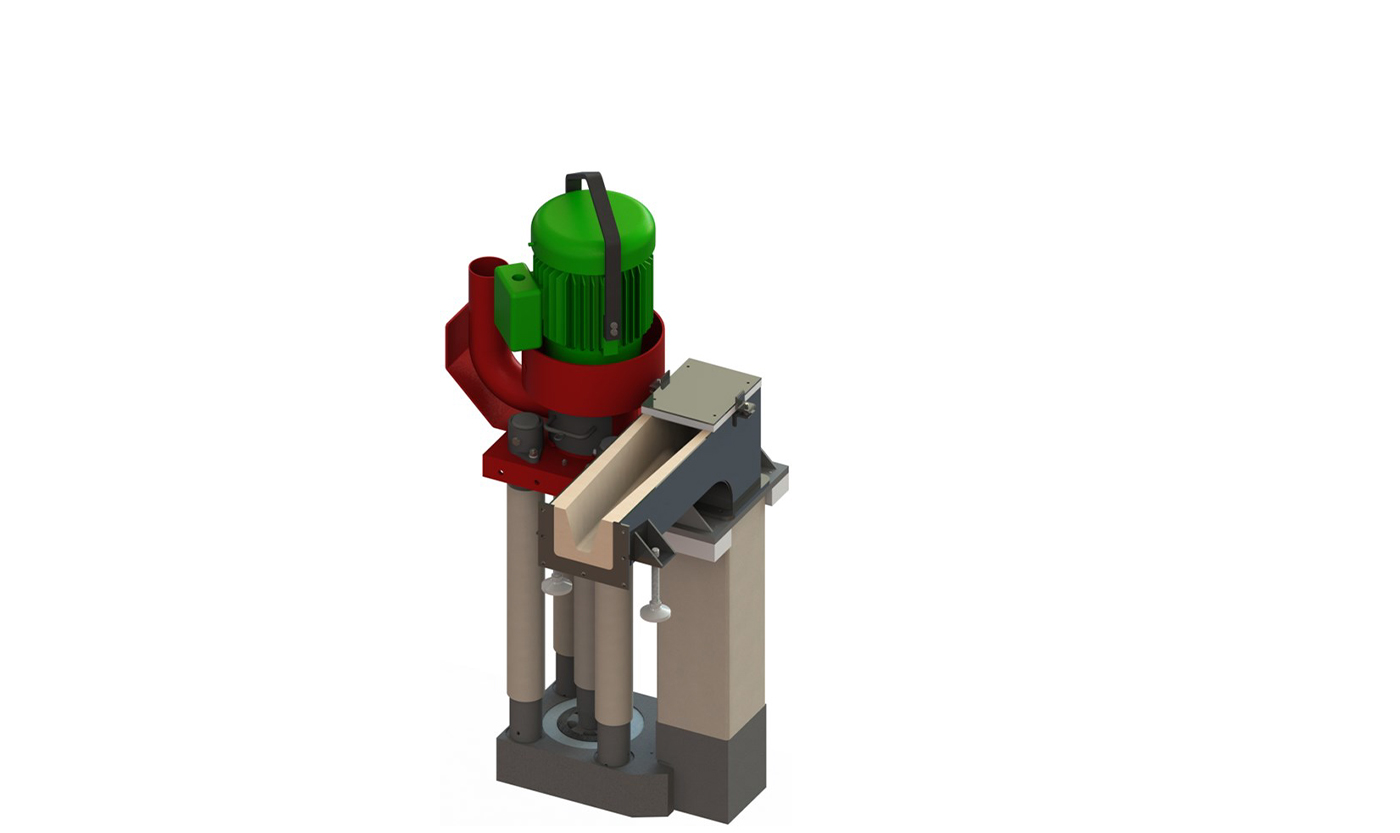

HYDRA Transfer Pump

Configured with a Launder

Launder Configuration Benefits:

- All metal movement is subsurface for quiet, turbulent-free transfers to maximize metal quality and minimize dross formation.

- It can be used to fill ladles quickly and safely.

- Flow control can be automated to feed a continuous casting operation accurately.

- A special launder design can be used to dose accurate amounts for directly filling casting molds.

- Electrically driven, the pump offers variable flow rates.

- Launder can be directed left, right, or straight ahead.

- The pump, riser, and launder are all attached together, making inserting and removing from the metal easier.

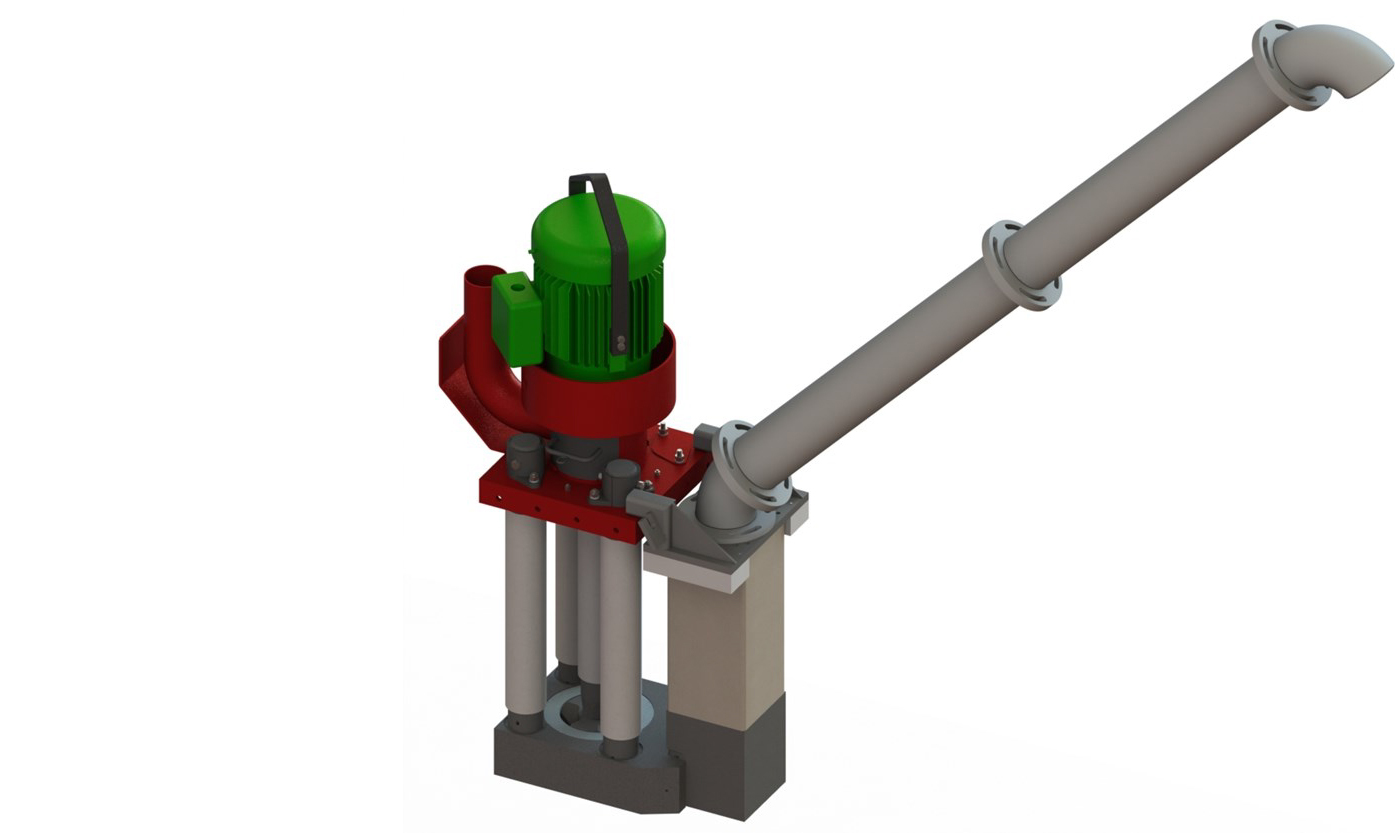

HYDRA Transfer Pump

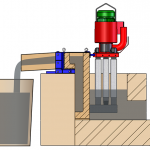

Configured with Piping

Transfer Pipe Configuration Benefits:

- The pump can generate greater pressure for those applications that need to deliver metal to a higher point.

- Great for filling tall ladles, transfers between furnaces, and other applications.

- It can be used with heated piping to accurately dose directly into molds or the shot sleeve of die casting machines. Offers faster shot times, larger doses, and shorter cycle times than other available technologies—all while maintaining an accurate dose.

- A tightly sealed transfer passageway ensures higher lifts and accurate doses.

- The pump offers variable flow rates for use with various requirements.

FEATURES

- Outlet can be configured with a launder, transfer piping, or heated piping

- Versatile outlet configuration capable of adapting to your requirements

- Sealed transfer pathway to improve overall transfer effectiveness

- Transfer piping option for high-lift situations

- Variable pressure ability to generate significant pressure as needed

BENEFITS

- Operational adaptability to choose the configuration based on your needs

- A sealed pathway means that transfers are more consistent and reliable

- Optimal metal quality with the launder configuration leads to minimal dross

- Quick and precise dosing facilitated by heated piping, maintaining a bias

- Suitable for settings with space constraints due to its small size

PROCESS INFO

OTHER PROCESSES

Molten Metal Transfer

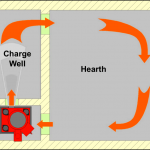

Furnace Circulation

Degassing Process

Gas Injection

Molten Metal Transfer

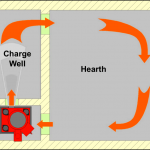

Furnace Circulation

Degassing Process

Gas Injection