Molten Metal Transfer

Quiescent flow for improved metal quality eliminates metal surges downstream, ensuring the integrity of filter/degas processes.

- When the pump turns on, it forces metal into the insert raising the metal level into the launder and down-stream or into the transfer ladle.

- Pump draws metal in from the middle of the bath depth for maximum metal quality

- Use laser metal sensor to constantly adjust speed of pump to maintain the metal level in launder at constant level

- Metal level in furnace can vary, but pump can maintain level in launder for a constant flow rate

- When pump stops, metal flows out of the launder or back into furnace and returns to present level in furnace (metal flows back through the pump)

Transferring metal is a critical step in most molten metal processes as it effects metal quality, productivity, the amount of waste, and overall safety.

Transferring molten metal can occur when filling ladles, transfer between furnaces, feeding casting lines, and filling ingot and sow mold lines.

Traditional metal transferring can be effective, but not always efficient or safe. Today there is a need for improved molten metal transfer methods that will improve metal quality through quiescent flow, improve flow control, generate more lift (elevation), reduce transfer time, reduce costs and waste, and improve safety of operators.

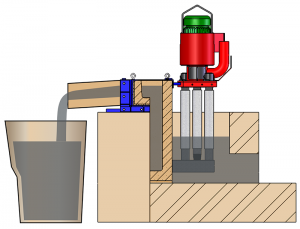

In an effort to improve overall performance and reliability of metal transfer, MMEI’s Launder Transfer System addresses traditional method’s short-comings. How does it work? When the pump turns on, it forces metal into the transfer well. The metal level rises in the transfer well and fills the launder as metal flows downstream. A pump draws metal in from the middle of the bath depth for maximum metal quality. Metal levels in furnaces can vary, but the right pump can maintain proper levels in launder for a constant flow rate.

MMEI’s custom-engineered Launder Transfer Pump System utilizes a specially designed molten metal pump with an insert or baffle board in the transfer well. A launder will be fabricated to attach to the insert or well for transfer into the ladle. Optional metal level sensors are available.

The MMEI system offers an improved process that will transfer metal faster with precision flow rates. Quiescent flow for improved metal quality eliminates metal surges through downstream process ensuring the integrity of filter/degas processes. It pulls metal from middle of bath for best metal quality, not from top or bottom. There’s no need to tilt a furnace or stop other processes such as melting and alloying.

At the heart of the Launder Transfer System is the Launder Transfer Pump. MMEI Transfer Pumps improve the method of transferring metal by achieving better metal lift, eliminating casting pits, and allows for insertion of new elements into exiting process which are limited by lack of elevation.

Launder Transfer Pumps from MMEI offer reduced costs by having fewer operating parts, reduced dross formation from quiescent movement, reduced tapout cone usage and replacement. Now there’s no need to tilt a furnace or spend time maintaining a constant metal level in the old launder.

MMEI’s revolutionary transfer system reduces overall costs, energy, effort and maintenance while providing a safer work environment for operators and all those involved.