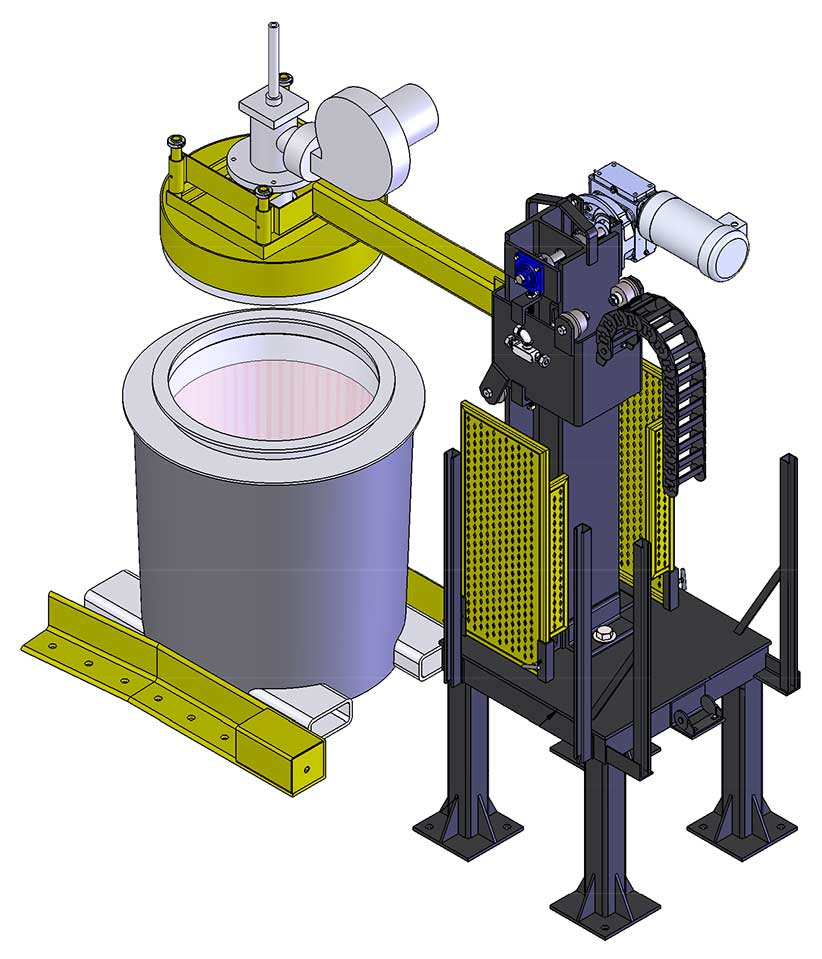

Preheating for Non-Ferrous Foundries

Preheating stations can be a valuable asset to the metal melting process.

To prevent temperature decrease while transferring metal, the transfer ladle can be preheated with a natural gas burning system. Preheating improves performance by….

Preheaters can also be used to keep components warm and, more importantly, moisture free. This speeds up the entire process and limits hazardous conditions. Moisture is removed from the ladle to avoid formation of gas / reaction in the liquid metal.

Extreme temperature differences or accumulated moisture can cause catastrophic failures.

- Keep spare parts warm and ready for use

- Remove accumulated moisture which occurs as ladle cools

- Natural gas or propane

- ~40,000 BTU/hour