Molten Metal Circulation Pumps

Circulates. Increases Melt Rate. Generates More Metal Flow.

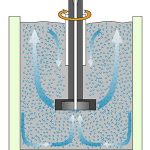

Industry leading fluid-dynamic advanced rotor—pumps more metal per revolutions, generating more metal flow than others.

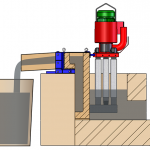

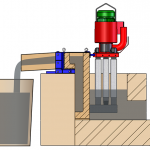

MMEI circulation pumps are one of the easiest and best ways to dramatically improve the productivity and efficiency of your furnace. Proven performers in even the toughest applications, our circulation pumps will increase your melt rate while reducing the energy needed to melt each pound of non-ferrous metal. As a result, you will get more productivity out of your furnace while lowering your melting costs.

RESOURCES

MOLTAR

BIG FOOT

THOR

WORKHORSE

MINI taur

Every Foundry is Unique!

Our product line has overlapping capacities by design. Contact our sales engineers to discuss your specific application and which circulation pump is best for your operation.

MODEL

—

Moltar

Bigfoot

Thor

Workhorse

Mini Taur

FURNACE

CAPACITY

100,000 to 300,000 lbs

85,000 to 275,000 lbs

100,000 to 200,000 lbs

40,000 to 125,000 lbs

10,000 to 50,000 lbs

RECOMMENDED

WELL SIZE

48″ x 48″

48″ x 48″

48″ x 48″

36″ x 36″

24″ x 24″

ROTOR

DIAMETER

16″

14″

12″

10″

7″

FEATURES

- Five sizes

- Unique mixed-flow rotor provides higher flow rates

- Non clogging rotor design

- Advanced sleeve protection on shaft and posts

- Robust design

- Self-aligning design

- Gas injection capable

BENEFITS

- We have a size to fit your application

- Increases furnace melt rate and improves energy efficiency

- Designed to pass solids and reduce rotor breakage

- Increases service life of shaft and rotors

- Longer service life, lower operating cost

- Easy to assemble and rebuild. Reduces maintenance time.

- Can be used to de-mag or degas bath

PROCESS INFO

OTHER PROCESSES

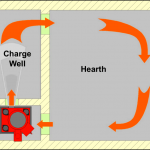

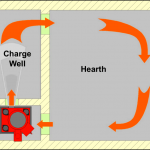

Furnace Circulation

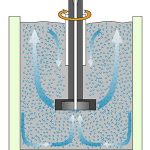

Degassing Process

Molten Metal Transfer

Gas Injection

Furnace Circulation

Degassing Process

Molten Metal Transfer

Gas Injection