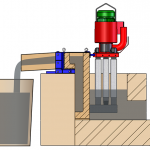

Conventional Transfer Pumps with Piping

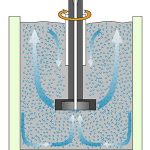

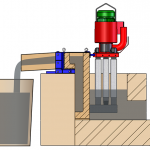

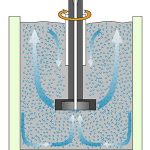

MMEI conventional Transfer pumps are most appropriate for ultra-high-lift applications. The Mini and Workhorse pumps will meet the majority of your conventional transfer applications. Both pumps are available in top and bottom feed versions and are designed for aluminum and zinc applications. The pumps can be driven by either air or the more controllable and economical electric motor. Unlike our competitor’s pumps, our risers are not structural members of the pump and can be easily replaced. The riser sits on a button located on the base and the riser clamp is attached to the motor mount with a bolt. The riser can be changed hot, limited down time.

Models:

WORKHORSE

MINI

MIGHTY MITE

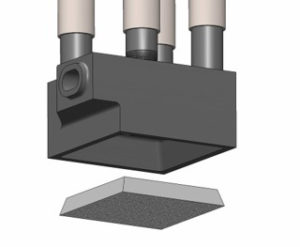

MMEI transfer pumps can also be used to filter your metal! We utilize a ceramic foam filter on the bottom of the pump, and our unique bottom feed rotor to deliver cleaner metal, every time!

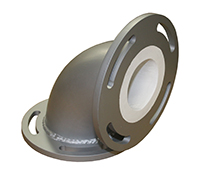

Refractory Lined Piping:

MMEI also supplies refractory lined piping that is used with our transfer pumps. Available in straight sections up to 48″ (1219 mm) long and elbow angles from 30 to 95 degrees.

Straights up to 48″ long

Elbows up to 95 degrees

FEATURES

- Available in 3 sizes – Workhorse, Mini & Mighty Mite

- Proprietary mixed-flow rotor design generates more flow

- Rugged design with extra-large components

- Advanced material protective sleeves on shaft and posts

- Riser is non-structural component

- Driven by a high-efficiency, electric motor

- Refractory lined pipe available to complete your pump

- Available with a filter on inlet to remove impurities

BENEFITS

- Right size pump for your application

- Generates more flow and higher lift for faster transfers

- Withstands harsh environment for longer service life

- Increases service life of components

- Riser can be “hot changed” quickly, reducing downtime

- Provides precise control of the flow, reduces electric costs

- Safely deliver the metal to where you need it

- Deliver cleaner metal, improve quality of castings

PROCESS INFO

OTHER PROCESSES

Molten Metal Transfer

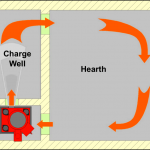

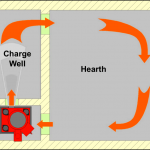

Furnace Circulation

Degassing Process

Gas Injection

Molten Metal Transfer

Furnace Circulation

Degassing Process

Gas Injection