MMEI in the News

News

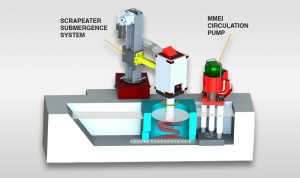

ScrapEater light gauge scrap melting system for higher metal recovery.

The ScrapEater improves metal reclamation significantly. While exact rates may vary, high rates of metal recovery up to 98% have been proven.

- Submerges lightweight scrap like chips and turnings quickly – over 20,000 lb. per hour

- Increases metal recover

- The cleaner and drier the chips are, the better the recovery

- Minimal surface turbulence means less dross

- Graphite components increase service life and improve performance

- Rugged, versatile system for handling many varieties of scrap

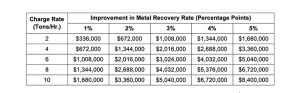

The above calculations are based on the price of aluminum at $1/lb, 24 hours/day charging, 350 days/year operation

Start recovering more metal today.

Smarter Metalcasting Solutions

April 12–15, 2025 | Georgia World Congress Center | Booth #2507

Join MMEI at CastExpo 2025, the must-attend event for metalcasters, happening April 12–15 in Atlanta. As a leader in molten metal pump technology, we’re bringing high-performance solutions designed to extend pump life, improve metal quality, and maximize operational efficiency. Visit Booth #2507 to see how our innovative pump solutions can:

- Extend Pump Life – Engineered for durability in the toughest environments.

- Improve Metal Quality – Reduce oxides and inclusions for cleaner casting.

- Enhance Efficiency – Lower maintenance and energy costs for better production uptime.

Our experts will be on hand to discuss how our technology helps foundries achieve safer, more efficient, and cost-effective operations.

We look forward to connecting with you in Atlanta!

Molten Metal Quick Immersion Transfer Pump

The Raptor transfer pump from MMEI is an ideal solution for pumping out furnaces and filling containers like crucibles, molds, ladles, and ingots with aluminum and zinc. It has controls and a built-in cooling blower to keep the highly efficient electric motor cool. Electric motor transfer pumps are more reliable than air-powered ones, reducing the risk of failure during transfer and ensuring consistent metal delivery.

- Lightweight, portable, and easily moved to different power sources

- High flow rates up to 800 lbs per minute

- Heavy duty shaft for longer service life and easy installation

- Rotor designed to minimize turbulence and avoid creating a vortex

- Available in four lengths

With a compact base of only 10″ x 10″, the Raptor can fit through small openings while its wide outlet minimizes dross and provides quiescent metal flow. The variable speed control for adjusting metal flow saves money by eliminating the need for riser tubes and transfer piping, at higher performance and efficiency than standard pumps.

Improve quality and reduce downtime with MMEI.

Metal Transfers Made Easy with Hydra Pumps

A new, multi-configurable transfer pump for use with molten metal can be configured for use with launders, transfer piping, or heated piping for dosing.

LAUNDER CONFIGURATION

The cleanest transfers for minimum dross and maximum metal quality

- Subsurface metal movement for quiet, quality transfers

- Automated flow for accurate, continuous casting and variable flow rates

- Dose specific amounts for the direct filling of casting molds

- Flexible direction control: choose left, right, or straight

- Easy insert and removal with an integrated system of pump, riser, and launder

TRANSFER PIPE CONFIGURATION

Ideal for when high lifts are required

- High-pressure pump for elevated metal delivery

- Perfect for tall ladles and inter-furnace transfers

- Heated piping for precise mold and machine dosing

- Achieve faster, larger doses with shorter cycles

- Variable flow rates for diverse application needs

Discover HYDRA Transfer Pump’s unmatched versatility and peak performance across various applications.

MMEI would like to wish you a Merry Christmas and a Happy New Year

As the holiday season is upon us, we at MMEI would like to take a moment to express our gratitude to all our valued partners and customers. Your trust and collaboration are the foundation of what we do, and we’re deeply thankful for the opportunity to serve you.

Whether you’re preparing for upcoming projects or simply need advice about optimizing your metal casting processes, we’re here to help. Our team is ready to assist you with any questions or support you might need, from choosing the right molten metal pump to improving efficiency and safety in your operations.

Please don’t hesitate to reach out—we’re just an email or call away.

From all of us at MMEI, we wish you a Merry Christmas and a New Year filled with success, prosperity, and joy.

Always Trying to Make it Better

JEFF KELLER

CEO

Molten Metal Equipment Innovations

ARTICLE TAKEAWAYS:

- Molten metal transfer has a major impact on metal quality

- Better metal transfer from improved graphite, refractory & ceramic pumps

- Newer technologies have amplified the advantages of using a mechanical pump

The transfer of molten metal is a fundamental process used in virtually every

stage of making nonferrous cast parts. Like most industrial processes, it has

evolved over time as innovators have introduced new ways of doing things.

In the beginning, gravity was the primary technology deployed in the process

of getting molten metal from point A to point B. It is still used today, but as

Mr. Newton taught us, it has limitations.

MMEI is at ALUMINIUM Düsseldorf 2024

MMEI solves metal movement challenges with innovative products. We offer a complete line of engineered molten metal pumps, circulation pumps, and transfer pumps along with scrap submergence systems, degassing units, and replacements parts – all designed to withstand harsh foundry requirements.

[ LinkedIn Post ]

Rotary Degassing Systems from MMEI achieve better degassing results – in less time – at less cost

MMEI offers a complete range of rotary degassing units featuring the latest advancements in technology to ensure repeatable results – faster:

• Automatic ladle degassing stations

• In-line units with single and multiple spinning rotors

• Portable units

• Mobile units for treating crucibles throughout the plant

• Custom units for degassing over-the-road ladles and other large vessels

• Fuel injection units

Units are available with easy to operate electric and gas controls. Timers, temperature sensors, digital readouts and other enhancements are incorporated into controls packages and are designed to be operator friendly. MMEI gas controls include separate flow meters for both the purge and main gas. Smaller, portable units are available with pneumatic controls.

Additionally, MMEI uses graphite components which are critical to successful metal treatment. The patented QUAD-Zilla® rotor provides superior metal treatment by shearing the gas and pushing outward and drawing metal from bottom, eliminating untreated dead zones. This unique rotational movement is specific to the QUAD-Zilla.

Circulate. Melt. Generate More Metal Flow

Industry leading fluid-dynamic advanced rotor— pumps more metal per revolution, generating more metal flow

• Increase your melt rate while reducing the energy needed to melt each pound of non-ferrous metal • Reduce energy consumption

• Eliminate temperature stratification & hot spots in furnace

• Increase service life – premium materials and designs that hold up in a plant environment

• Thermal and mechanical properties withstand demanding environment

• Perfect for mixing metal for fast alloying and homogenization

• Easy to operate, build, and maintain

• Optional gas injection

• Available in various sizes to fit your furnace

Defect Prevention In

Molten Metal Processing

Metalcasting is vulnerable to defects at various stages, often becoming noticeable only later, leading to costly repairs. It’s essential to identify and address these issues early in the process to ensure high-quality final products.

In this featured article, we explore effective strategies to prevent defects in metalcasting. For instance, implementing a filtered launder-transfer system can remove impurities from the metal, preventing downstream issues. Each phase of the process, from metal transfer to quality-focused activities, plays a crucial role in defect prevention. By considering the entire transfer system and focusing on technical specifics, complex defects can be avoided.

Enhance quality, increase productivity, and reduce downtime with MMEI.

Create Your Personalized Online Store Through MMEI

ONLINE ORDERING MADE EASY

Molten Metal Equipment Innovations has an online ordering portal through our website that is incredibly easy to use.

The first step is to contact MMEI and let us know that you’d like access. Within a day, we will create login credentials and set up a store with only the parts that you use. All parts are sorted by equipment type (e.g., “Workhorse” or “Scrapeater,” etc.) and include clear descriptions and images to make identifying the parts that you need a breeze.

Once an order is placed, our office will immediately receive it, enter it into our system, send you an order confirmation, and complete delivery. Each order is still entered individually to ensure that everything is correct.

It’s simple to use! Contact us, and we will set you up today!

You can count on MMEI to lead in providing advanced productivity tools to help you do your job more efficiently.

New Demands Require New Tools in the Toolbox

A prominent business innovation leader said, “I have no issues with innovation; my mind generates more ideas than I can act on. My issue is execution.”

The die casting industry has seen some significant innovations of late, including ever-larger presses capable of making ever-larger parts and eliminating costly assembly to drive competitive advantage further. The advent of gigacasting or megacasting technology has required the industry to develop new tools for the toolbox to support this type of production.

ARTICLE TAKEAWAYS:

- Aluminum Gigacasting are pushing boundaries in the next generation of e-vehicles

- Requires new tools in the toolbox from suppliers to improve productivity

- More metal, higher consistency, and less variation

MMEI is adapting to these changes by reevaluating our equipment to meet the needs of gigacasting. Our testing results show a high level of consistency in metal delivery for maintaining the highest quality in die casting. Looking Forward, we are excited to continue supporting the trend toward larger presses and exploring ways to enhance our systems to provide even larger and more consistent shot sizes.

Quick and Flexible Metal Transfer Solutions

MMEI’s Speed Demon quick immersion pump, tailored for low lift applications, is perfect for aluminum and zinc. The Speed Demon transfer pump can be used in a very small opening (8 to 10 in) and is designed to be submerged and operate quickly—within minutes.

This transfer pump has a 6” diameter riser, fitting easily in tight spaces. It can be used to pump out crucibles, ladles, and degassing boxes, and with flow rates of up to 300 lbs (135 kg)/min, it can even pump out larger furnaces.

The Speed Demon is lightweight and portable, allowing for easy movement throughout a plant. It is engineered to provide a long service life and is easy to assemble and repair. It has a pneumatic motor for variable speed operation, allowing for varying metal flow.

The Speed Demon Transfer Pump from MMEI is a flexible solution for transferring metal on demand. Versatile, mobile, and always ready for action, it’s the essential tool for effortless maintenance tasks in every plant environment.

New Demands Require New Tools In The Toolbox

A prominent business innovation leader said the other day something along the lines of “I have no issues with innovation, my mind generates more ideas than I can act on. My issue is execution.” The die casting industry has seen some significant innovation of late in ever larger presses capable of making ever larger parts and eliminating costly assembly, to further drive competitive advantage. The advent of gigacasting or megacasting technology has required the industry to develop new tools for the toolbox to support this type of production.

ScrapEater Light Gauge Scrap Melting System for Higher Metal Recovery

The ScrapEater will improve your metal reclamation significantly. While exact rates may vary, high rates of metal recovery up to 98% have been proven with MMEI’s ScrapEater.

This durable melting system is easy to install, maintain, and operate.

• Submerges lightweight scrap like chips and turnings quickly – 20,000 lb per hour & more

• Increases metal recovery

• The cleaner and drier that the chips are, the better the recovery

• Minimal surface turbulence means less dross

• Graphite components increase service life and improve performace

• Rugged, versatile system for handling many varieties of scrap

Molten Metal Quick Immersion Transfer Pump

The Raptor transfer pump from MMEI is an ideal solution for pumping out furnaces and filling containers like crucibles, molds, ladles, and ingots with aluminum and zinc. It has controls and a built-in cooling blower to keep the highly efficient electric motor cool. Electric motor transfer pumps are more reliable than air-powered ones, reducing the risk of failure during transfer and ensuring consistent metal delivery.

Features

- Lightweight, portable, and easily moved to different power sources

- High flow rates up to 800 lbs per minute

- Heavy duty shaft for longer service life and easy installation

- Rotor designed to minimize turbulence and avoid creating a vortex

- Available in four lengths

With a compact base of only 10″ x 10″, the Raptor can fit through small openings while its wide outlet minimizes dross and provides quiescent metal flow. The variable speed control for adjusting metal flow saves money by eliminating the need for riser tubes and transfer piping, at higher performance and efficiency than standard pumps.

Improve quality and reduce downtime with MMEI.

Metal Transfers Made Easy with HYDRA Pumps

A new, multi-configurable transfer pump for use with molten metal can be configured for use with launders, transfer piping, or heated piping for dosing.

Launder Configuration

The cleanest transfers for minimum dross and maximum metal quality

- Subsurface metal movement for quiet, quality transfers

- Automated flow for accurate, continuous casting and variable flow rates

- Dose specific amounts for the direct filling of casting molds

- Flexible direction control: choose left, right, or straight

- Easy insert and removal with an integrated system of pump, riser, and launder

Transfer Pipe Configuration

Ideal for when high lifts are required

- High-pressure pump for elevated metal delivery

- Perfect for tall ladles and inter-furnace transfers

- Heated piping for precise mold and machine dosing

- Achieve faster, larger doses with shorter cycles

- Variable flow rates for diverse application needs

Discover HYDRA Transfer Pump’s unmatched versatility and peak performance across various applications.

MMEI Wishes You a Merry Christmas & Happy New Year

We will be closed December 25th, 26th, and January 1st for the Holidays.

What Did You Say

Just use ChatGPT says one of my kids…. who knows, maybe someday they will be right. For now, we’re going to have to keep on doing it the old-fashioned way and engage in actual dialogue.

The importance of clear communication in business cannot be overstated. Every installation requires a partnership in communication and expectations. What’s spoken is not always what’s heard, and in today’s fast-paced world, misunderstandings can be costly. Jeff Keller, CEO of Molten Metal Equipment Innovations, discusses the essential pillars of effective communication and why it remains crucial even in the age of AI technologies.

WMMEI Dosing Pumps – Ultimate Casting Accuracy

Accurate dosing, exceptional repeatability, rapid transfer rates, and shortened cycle times – all made possible by MMEI’s new Dosing Pump. The pump ensures molds and die casting machines receive precise metal dosage, leading to superior casting quality.

With three available sizes – the MINI, WORK-HORSE, and KONG – our Dosing Pump adapts to your needs.

Pump Features & Benefits

- Reliable variable speed motor for adjustable dosing rates

- Robust 3 and 4 post design for precise alignment and integrity

- Sturdy shaft extends service life and minimizes vortexing

- Special rotor design for swift, targeted flow from the highest quality metal source

- Unique multi-material ensures sealed metal flow

- Quick-change piping connections for easy adjustments without pump removal

Integrate for Excellence

Complete Dosing System: MMEI’s dosing pumps are just one part of our comprehensive dosing system. Our recommended system includes metal treatment, continuous stirring, heating, and level control, all working together to guarantee repeatable, high-quality results.

Accurate casts. Amplified results.

What did you say?

Just use ChatGPT says one of my kids…. who knows, maybe someday they will be right. For now, we’re going to have to keep on doing it the old-fashioned way and engage in actual dialogue.

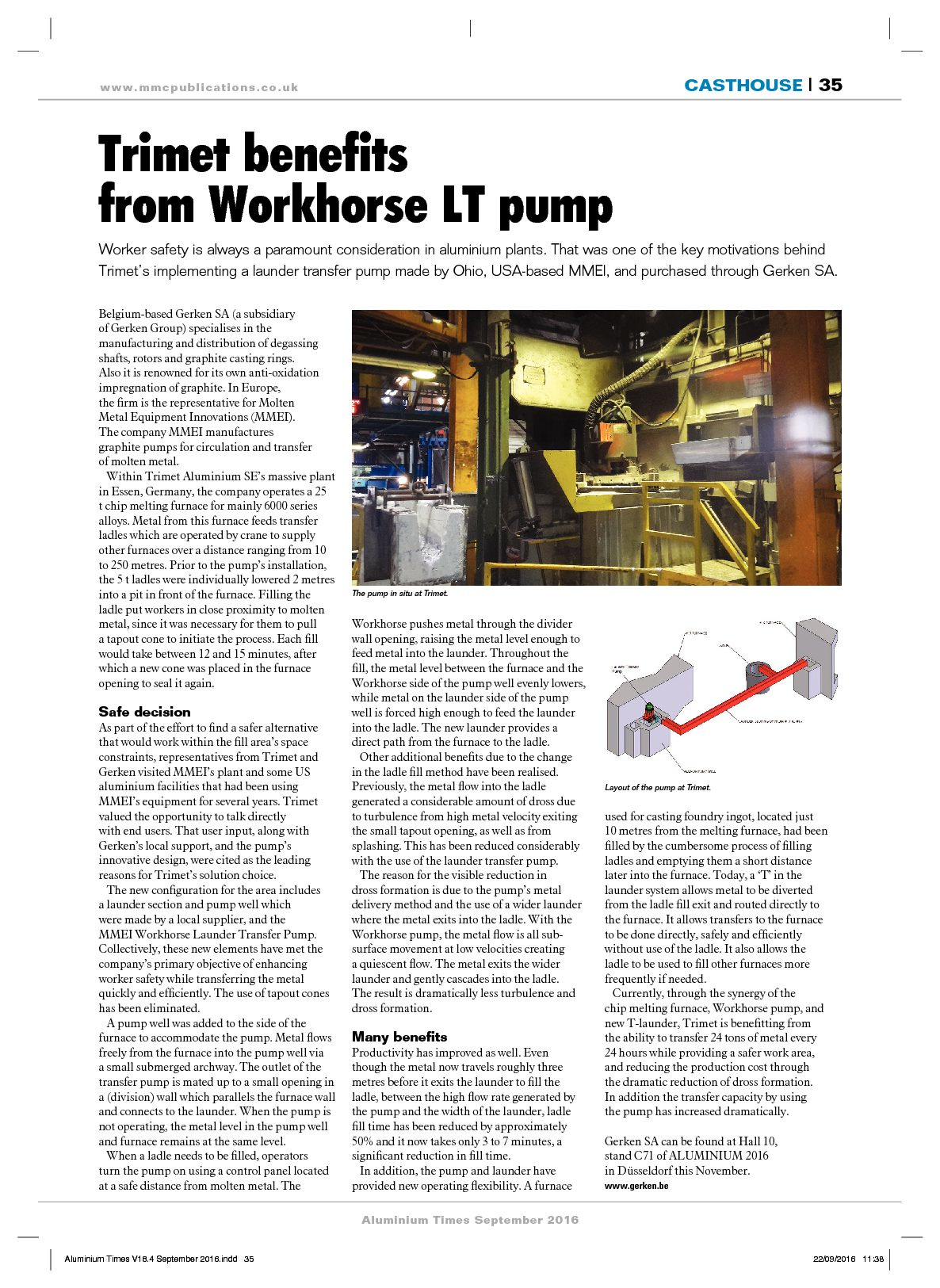

MMEI Launder Transfer Pumps Engineered For Efficiency

Better.

MMEI’s Launder Transfer Pump transfers metal directly to the launder – eliminating the need for a riser and refractory lined piping to transfer the metal. The result? High flow rates achieved at lower velocities.

Cleaner.

The low turbulence, quiet flow of metal provides cleaner metal with reduced dross formation. The open access of the launder allows for easier cleaning and maintenance.

Safer.

Operators remain at a safe distance during the transfer process. Flow stops immediately under the operator’s control. No tapouts to pull, leak, or replace reduces exposure to the operators.

MMEI Launder Transfer Pumps are versatile and durable.

Available in multiple sizes, easily maintained, and built rugged for a long production life.

They can be used in many ways to improve productivity:

- Fill ladles quickly

- Transfer metal directly between furnaces (even when furnaces are at different elevations)

- Feed casting lines in places of expensive tilting furnaces

Transform Your Metal Quality, Trust in MMEI’s Launder Transfer Pumps.

MMEI Circulation Pumps Built for Superior Performance

Circulate. Melt. Generate More Metal Flow.

Industry leading fluid-dynamic advanced rotor- pumps more metal per revolution, generating more metal flow than others.

• Reduce energy consumption

• Eliminate temperature stratification & hot spots in furnace

• Increase service life – premium materials and designs that hold up in a plant environment

• Thermal and mechanical shock properties withstand a demanding environment

• Perfect torn mixing metal for fast alloying and homogenization

• Easy to operate, build, and maintain

• Optional gas injection

• Available in various sizes to fit your furnace

Get it right, right from the start with circulation pumps from MMEI.

Online Ordering Made Easy

Molten Metal Equipment Innovations has online ordering through our website that is incredibly easy to use.

The first step is to contact MMEI and let us know that you’d like access. Within a day, we will create login credentials and set up a store that has only the parts that you use. All parts are sorted by equipment type (e.g., “Workhorse” or “Scrapeater,” etc.) and include clear descriptions as well as images of the parts to make identifying the parts that you need a breeze.

Once an order is placed, our office will immediately receive your order, enter it into our system, send you an order confirmation, and complete delivery. Each and every order is still entered individually to ensure that everything is correct.

It’s really simple to use! Contact us and we will get you set up today!

Why To & How To—

Clean Your Furnace

There is a stigma in the foundry business that cleaning your furnace should make you the star of the show “Dirty Jobs.” It’s not fun, it’s always hot and it can indeed be dirty!

It may also be that there are few things more important than keeping your furnace clean as it relates to your operation’s profitability. So, let’s take a closer look, not only at the “how to,” but at the “why to” clean your furnace and your furnace wells regularly. We will see that there are some aspects of this that will certainly vary from foundry to foundry, but in all cases, there are principles that will drive improvement in your business performance if you adhere to them. Your two largest costs in this business are raw material and energy. Good cleaning practices will provide a significant increase in throughput while reducing the energy required. These outcomes can be measured and will correlate directly with your income statement each month.

ScrapEater Light Gauge Scrap Melting System for Higher Metal Recovery

This durable melting system is easy to install, maintain, and operate.

• Submerges lightweight scrap like chips and turnings quickly – 20,000 lb per hour & more

• Increases metal recovery

• The cleaner and drier that the chips are, the better the recovery

• Minimal surface turbulence means less dross

• Graphite components increase service life and improve performace

• Rugged, versatile system for handling many varieties of scrap

Molten Metal Quick Immersion Transfer Pump From MMEI

The Raptor transfer pump from MMEI is an ideal solution for pumping out furnaces and filling containers like crucibles, molds, ladles, and ingots. Driven by a highly efficient electric motor, it has controls and a built-in cooling blower to keep the motor cool. Electric motor transfer pumps are more reliable and consistent than air-powered ones, reducing the risk of failure during transfer and ensuring consistent metal delivery.

Designed for use with aluminum, the Raptor is lightweight, portable, and can be easily moved to different power sources. Its graphite body enables fast immersion for high flow rates of up to 800 lbs. (360 Kg) per minute. The pump is durable, built to last in harsh molten metal environments, and features a heavy duty shaft for longer service life and easy installation. The unique rotor design minimizes turbulence and avoids creating a vortex, making the Raptor stand out from other pumps on the market.

With a compact base of only 10″ x 10″ (254 x 254mm), the Raptor can fit through small openings, and its wide pump outlet reduces dross formation and provides quiescent metal flow. With variable speed control for adjusting metal flow, the Raptor transfer pump can save you money by eliminating the need for riser tubes and transfer piping while delivering higher performance and efficiency than standard pumps. Available in four lengths, the Raptor is the transfer pump you need.

Improve quality, productivity and reduce downtime with MMEI.

Merry Christmas & Happy New Year!

We will be closed December 23rd, 26th and January 2nd for the holidays. We will reopen January 3rd, 2023.

Launder Transfer Pumps Better, Cleaner & Safer Metal Transfer

BETTER

MMEI’s Launder Transfer Pump transfers metal directly to the launder – eliminating the need for a riser and refractory lined piping to transfer the metal. This means high flow rates can be achieved at low velocities.

CLEANER

The low turbulence, quiet flow of metal provides cleaner metal with reduced dross formation.

SAFER Operators remain at a safe distance during the transfer process. Flow stops immediately under the operator’s control. No tapouts to pull, leak or replace reduces exposure to the operators. Also, the open access of the launder allows for easier cleaning and maintenance. MMEI Launder Transfer

Pumps are available in multiple sizes, easily maintained and built rugged for a long production life. They can be used many ways to improve productivity: · Fill ladles quickly · Transfer metal directly between furnaces (even when furnaces are at different elevations) · Feed casting lines in place of expensive tilting furnaces Better metal transfer means higher metal quality.

Applications

Filling Ladles

Transfer Between Furnaces

Feeding Casting Lines

Back to Basics:

Lessons from Your Mother….

The road to getting back to “normal” is definitely routed through get “back to basics” town. It’s time we do some thinking about how we can return to those things that are so easy to ignore, overlook, or more accurately, just choose not to do.

Our sales team at Molten Metal Equipment Innovations spends lots of time in our customer’s facilities and some time in our own facility. In both places, they are constantly presented with simple opportunities to do things that can significantly impact the business operation. Most of these things are known, and it generally is just a question of making them a priority. Just like my mother would tell me to clean my room, and I’d find a way to do anything but that, we all have simple ways to get back to some of the basics when it comes to cleanliness and maintenance. Re-committing to these activities can provide major benefits to your operational and financial performance, and improve employee and customer satisfaction.

MMEI Pumps Power New Efficient Furnace for Toyota

July 8, 2022 – Deeside, Wales, UK

MMEI is proud to have contributed key components to a new aluminum furnace installation at the Toyota Deeside plant in Wales. MMEI’s equipment is designed and manufactured to support high-efficiency operation and long service life, making it an ideal choice for this installation. The new equipment will play a significant role in reducing carbon emissions at the plant, furthering Toyota’s goal of reaching net zero manufacturing carbon emissions by 2040.

The new furnaces — along with their integrated MMEI Mini Launder Transfer Pumps, Circulation Pumps, and Scrapeater chip melting systems — were officially activated on July 8th – National Manufacturing Day in the UK. Economy Minister Vaughan Gething said, “On National Manufacturing Day, I am delighted to help Toyota take their next step in their net zero mission with the new furnaces launched today.”

Using Available Data to Improve Performance and Generate New Revenue Streams

It seems fitting to begin this with a discussion of chips, as they are an all-consuming topic given how difficult they have become to procure. Gordon Moore predicted that the amount of information a microchip could process would double every two years, while the cost of that processing would decrease by 50% in the same time period. This is a revolutionary idea and has empowered a transformation in the way everything works. We have been reminded of this recently as the world’s chip shortage has been crippling to many industries and may lead to an entirely new round of innovation. Shifting away from the issue of being able to get chips at present, if we focus on what they can already do for us, I will posit that there is an abundance of available information not being used. If we put this information to better use it would provide opportunities for improvements within our own companies and allow companies to develop entirely new revenue streams.

Flexible Metal Transfer Solutions from MMEI

MMEI’s Speed Demon quick immersion pump is designed for low lift applications. Used for aluminum and zinc, the non-ferrous molten metal Speed Demon transfer pump can be used in a very small opening (8 to 10 in) and is designed to be submerged and operating quickly – within minutes.

With its 6″ diameter riser, this transfer pump provides a small footprint that can easily fit in small openings and tight spaces. This means it can be used to pump out crucibles, ladles, and degassing boxes. Since the Speed Demon transfer pump provides flow rates up to 300 lb (135 kg)/min, it can even be used to pump out of larger furnaces.

Lightweight and portable for easy movement throughout a plant, and engineered to provide a long service life, the Speed Demon transfer pump can be used in many applications. It is designed for easy assembly and repair, and with a pneumatic motor that allows for variable speed operation for varying metal flow.

The Speed Demon Transfer Pump from MMEI is a flexible solution to transfer metal on demand that every plant can use. It’s designed to be mobile, and ready to use at a moment’s notice. Perfect for any maintenance application.

New Molten Metal Quick Immersion Transfer Pump from MMEI

MMEI’s new Raptor transfer pump is the perfect solution to pump out your furnace or fill crucibles, ladles, molds or ingots. Driven by a reliable, high efficiency electric motor, this pump has mobile controls and an integrated cooling blower to make sure the motor is always cooled. Plus, electric motor transfer pumps are more reliable and consistent than compressed air supply, so it’s less likely to fail during transfer and will have the most consistent metal delivery.

Used for aluminum and zinc, the Raptor is lightweight, portable and can be moved around easily to plug into any receptacle. The pump body is made from graphite, which allows quick immersion for fast use with flow rates up to 800 lbs. (360 Kg) per minute. Although designed for easy assembly and repair, it’s also rugged and engineered to last in a harsh molten metal environment. The heavy-duty shaft is designed to maximize service life and simplicity of installation. The special rotor design pushes metal upwards which minimizes turbulence and does not create a vortex like other pumps on the market.

The Raptor’s base is only 10″ x 10″ (254 x 254mm). This small footprint allows access through small openings, while its wide pump outlet (launder connection) provides quiescent metal flow and reduces dross formation.

With variable speed operation and control for varying metal flow requirements, the Raptor transfer pump can help you eliminate the costly expense of riser tubes and transfer piping while providing higher performance and efficiency than standard pumps. Available in four lengths, this is the transfer pump you need to get the job done. Improve quality, productivity and reduce downtime with MMEI.

Merry Christmas & Happy New Year!

We will be closed December 24th, 31st and January 3rd for the holidays. We will reopen January 4th, 2022.

Increase Productivity with Smart Pump Technology

Smart Pump technology can automate decisions that improve furnace productivity while also increasing the metal pump service life. Measuring key data points, adjustments can be made to the speed of the pump or to stop the pump when conditions exist that could cause damage. Automatically adjusting the pump based on circumstances reduces the man-power required to operate the furnace.

Smart Pump Technology Components

• MMEI Circulation or Gas Injection Pump

• MMEI Smart Pump Control Panel

• HMI Touch Screen Interface

• Laser sensor for measuring metal depth

• PLC (Programmable Logic Controller)

Measures

• Metal Temperature

• Metal Depth from Laser

• Vibration Signal

• Pump Speed

• Pump Amp Draw

Improve quality, productivity and reduce downtime with MMEI.

A Case Study in Molten Metal Transfer

Simple Solutions That Work! (September 2021) – Manufacturing processes are perpetually evolving.

Much like the natural world, things that prove beneficial tend to stick around, while those things that are harmful or less useful are eliminated over time.

New Advances in Molten Metal Delivery in Large Cast Parts

Simple Solutions That Work! (April 2021) – Manufacturing is an iterative process whereby improvements generally occur over time and through a commitment to continuous improvements.

In the broader foundry and metal casting industries, advancements in technology are driven by the desire to improve quality, reduce costs and expand margins, both for the customer and supplier.

Larger Automotive Castings Drive Innovation in Molten Metal Delivery

Automotive design trends are fulfilling long-standing cost and safety objectives in auto production – which is guiding further advances in casting processes. One of the most rewarding aspects of working in the foundry industry is the rapid pace of change and the introduction of new ideas and technology. It may not appear this way as we observe “metalcasting” from a higher level, but as we study the design and innovation laboratories at the many companies that comprise this sector, we can see how the incentive to develop new and better ideas is always present. Most of these ideas take a considerable amount of time and resources to develop, and so often “new” ideas have been a long time in the making. Some of the exciting new trends in automotive casting are evidence of this process and will lead to significant changes in the coming years.

Merry Christmas and Happy New Year

We will be closed December 24th, 25th, 31st and January 1st for the holidays. We will reopen January 4th, 2021.

Defect Prevention in Molten Metal Processing

Simple Solutions That Work! (Sept 2020) – The old adage that metal casting is a blend of art and science certainly rings true. At virtually every stage of the process there are opportunities to create what will ultimately become a defect in the part you are making.

Transferring Smaller Amounts of Molten Aluminum, Safely and Efficiently

Sometimes transferring smaller amounts of molten aluminum present big problems. Niche technologies present solutions for specific applications.

In metalcasting our focus is typically on large-scale problems, as they often have the greatest impact on our business results. In the business of producing secondary aluminum or aluminum castings there is no question that often it is a game of scale and efficiencies applied to large amounts of metal, liquid or solid. However, there are times when there is a need to focus on smaller amounts of metal, and how to transfer it both safely and efficiently. For example: when liquid metal must be transferred out of a casting machine after a run, or when there is an alloy change. Another example is delivering small, accurate doses directly to a mold to make a single casting. Let’s look at some ways to use niche product technologies to facilitate the safe and efficient transfer of small amounts of liquid metal.

State-Of-The-Art Equipment

MMEI recently installed a new Johnford ST-100 Super Turning Center to produce a mix of complex and large parts—faster. Our 5 axis machining center has live tooling allowing for tooling changeovers with no downtime. With 100” of travel, it can handle our customers’ longest parts with ease, and adds great flexibility to the manufacturing of our core product range. Our reputation for delivering exceptional results has stood the test of time because of our commitment to continuous improvement in all aspects of our business. Please contact us to learn more about how our equipment can improve your furnace circulation and metal transfer process.

Introducing Our New Smart Pump Animation

Using Smart Technologies to Circulate & Transfer Molten Metal

Simple Solutions That Work! (April 2019) – It would seem to state the obvious that the interface between machines and human beings is at the center of metal processing. Over time the depth to which this relationship has developed has been the basis for the different phases of industrial “revolution.” The Internet of things (IoT) now enables an entirely new way to connect the many decentralized components of a system so that information can be shared and used in ways that was previously not possible.

Minimizing Dross Creation in Molten Aluminum Transfer

Simple Solutions That Work! (September 2018) – It is a simple enough concept that the goal of any molten metal processing business should be to finish the process with the amount of metal for sale that is as close as possible to the amount you started with.